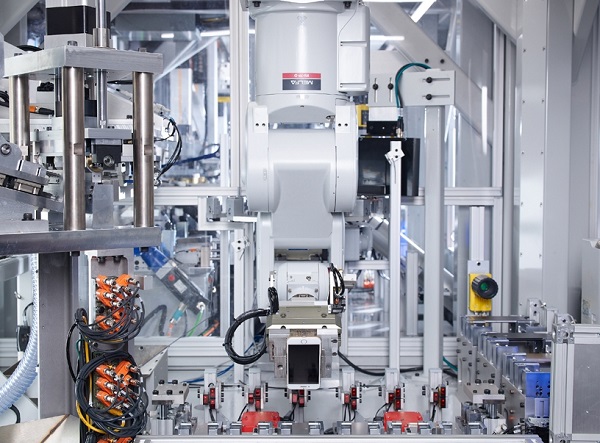

Cupertino (California), Apple on Thursday announced to expand its global recycling programmes and introduced Daisy, its recycling robot that is capable of disassembling 200 iPhones per hour.

US customers can send their iPhones to be disassembled by Daisy which is 33 feet long, has five arms and can methodically deconstruct any of 15 iPhone models.

Daisy will disassemble and recycle select used iPhones returned to Best Buy stores throughout the US and KPN retailers in the Netherlands, the company said in a statement ahead of Earth Day that falls on April 22.

Apple also announced the opening of its “Material Recovery Lab” dedicated to discovering future recycling processes in Austin, Texas.

The Lab will work with Apple engineering teams as well as academia to address and propose solutions to today’s industry recycling challenges.

“Advanced recycling must become an important part of the electronics supply chain, and Apple is pioneering a new path to help push our industry forward,” said Lisa Jackson, Apple’s vice president of Environment, Policy and Social Initiatives.

Apple has received nearly one million devices through its programmes and each Daisy can disassemble 1.2 million devices per year.

In 2018, the company refurbished more than 7.8 million Apple devices and helped divert more than 48,000 metric tons of electronic waste from landfills.

Daisy can take apart iPhones to recover materials such as cobalt, aluminum and tin, which are then recycled back into the manufacturing process.

Once materials have been recovered by Daisy, they are recycled back into the manufacturing process.

For cobalt, which is a key battery material, Apple sends iPhone batteries recovered by Daisy upstream in its supply chain.

They are then combined with scrap from select manufacturing sites and, for the first time, cobalt recovered through this process is now being used to make brand-new Apple batteries.